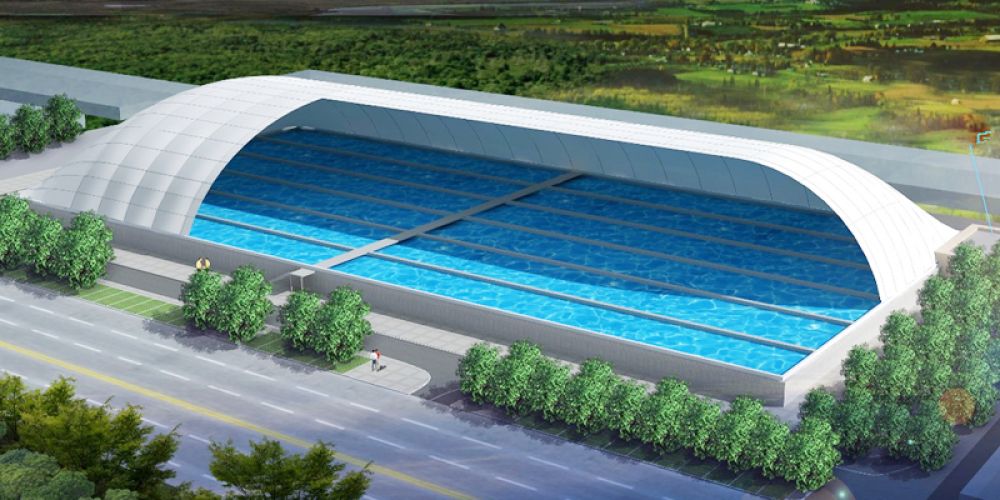

Air-supported structures maintain their shape through internal and external air pressure differences, eliminating the need for traditional beams or columns. This allows for large-span spaces (up to 180 meters) while reducing material usage and construction complexity. The system achieves lightweight, column-free designs.

High-strength, lightweight, and durable polyester fiber or PTFE membranes are used, offering excellent tensile strength and self-cleaning properties. The membrane surface is coated with PVDF or laminated with PVF film, providing up to 25% light transmittance for natural lighting. The material complies with B1-grade fire safety standards and meets weather resistance requirements.

Factory-prefabricated components enable on-site assembly in as little as 10 days for small/medium structures and ~2 months for large projects (including groundwork). Modular designs allow for reuse and relocation, ideal for temporary or seasonal applications.

Smart monitoring systems regulate internal air pressure, temperature, and humidity in real time. Dual backup air supply systems ("active-standby") ensure operation in extreme weather, with emergency power to handle outages.

The pneumatic system eliminates internal columns, enabling uninterrupted spans exceeding 100 meters (up to 180 meters). This is ideal for sports venues, warehouses, and other applications requiring vast open areas.

Ultra-lightweight membranes (<3 kg/m²) minimize inertial forces during earthquakes. A diagonal cable-stayed stabilization system withstands 12-level typhoons and 50+ kg/m² snow loads. In seismic events, structural collapse to 2 meters above ground takes ~30 minutes, ensuring safe evacuation.

The airtight, insulated design reduces energy consumption to 10–25% of conventional buildings, achieving >80% overall energy savings. Membranes are recyclable, and construction generates zero waste, aligning with green building principles.

Widely applicable in aerospace, renewable energy, environmental projects, and urban construction. The sealed structure blocks noise and dust, ideal for noise-sensitive or dense urban areas.

These features highlight the efficiency, flexibility, safety, and sustainability of air-supported membrane structures, positioning them as a leading innovation in modern architecture.