Composite materials are widely used in the aerospace field and have significant advantages. The following is an introduction from three aspects: application scenarios, advantages, and specific cases:

Application scenarios

Structural components: Composite materials are used to manufacture key structural components such as aircraft wings, fuselages, tails, landing gear, and engine compartments. These components need to withstand various forces and stresses during flight, and the high strength and light weight of composite materials make them an ideal choice.

Interior components: Inside the aircraft, composite materials can be used to manufacture panels, floors, seat structures and other components. Their lightweight properties help improve the aircraft's payload capacity and fuel efficiency.

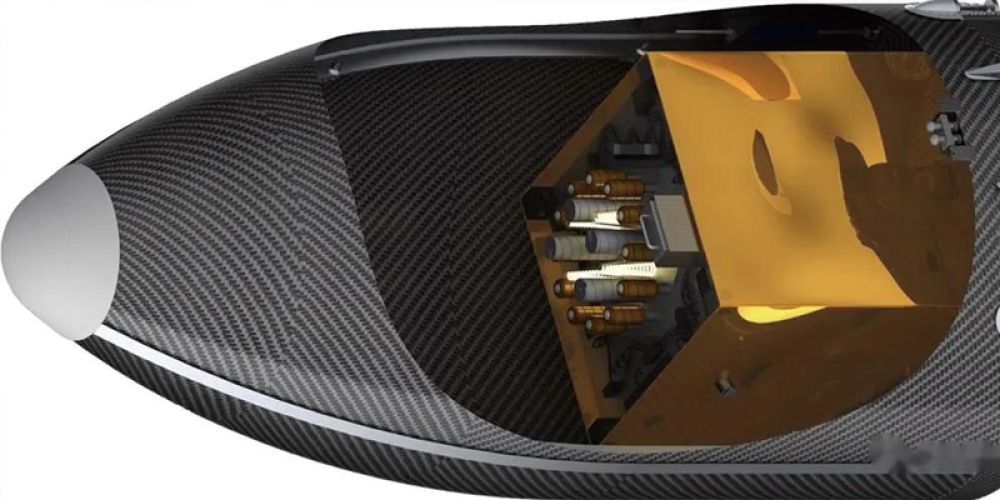

Engine components: Composite materials have penetrated into the core components of aircraft engines, such as fan blades and casing materials. These components need to withstand extreme temperatures and stresses, and the high temperature and corrosion resistance of composite materials enable them to do so.

Spacecraft components: In spacecraft, composite materials are used to manufacture components such as main cargo doors, pressure vessels, and heat shields. These components need to meet strict lightweight and environmental stability requirements.

Advantages

Lightweight: Composite materials have the characteristics of low density and high strength, which can significantly reduce the weight of aerospace vehicles. This helps reduce fuel consumption, improve flight performance and endurance.

High strength and stiffness: By combining high-strength fibers with matrix materials, composite materials have excellent mechanical properties. They can withstand complex load conditions and maintain structural stability.

Corrosion and high temperature resistance: Composite materials have good corrosion resistance and high temperature resistance, and can maintain stable performance in harsh aerospace environments.

Design flexibility: Composite materials can be customized according to specific needs to meet the specific requirements of different components. This flexibility makes composite materials have a wide range of application prospects in the aerospace field.

Specific cases

Aircraft application: The eight-seat commercial aircraft Learfang 2100, which is made entirely of carbon fiber composite materials in the United States, has successfully completed its test flight. The aircraft weighs only 567kg and is known for its compact structure and light weight. The Boeing 787 aircraft uses a large number of composite materials as the main load-bearing structure, which not only reduces weight but also improves the various flight performance of the aircraft.

Space shuttle application: The Columbia space shuttle uses a large number of advanced composite materials, such as the main cargo door made of carbon fiber/epoxy resin, and the pressure vessel made of Kevlar fiber/epoxy resin. The application of these composite materials enables the space shuttle to reduce weight while maintaining structural strength and stability.

Satellite and rocket applications: In satellites and rockets, composite materials are used to manufacture support structures, antenna panels, battery panels and other components. For example, the truss structure of my country's first lunar exploration satellite, Chang'e-1, uses composite materials to meet the requirements of lightness, reliability and stability.