Research on Durability of Heat-Sealed Seams in ETFE Membranes Under Extreme Environments

Abstract

This study systematically investigates the tensile strength degradation rate of heat-sealed seams in ethylene tetrafluoroethylene (ETFE) membranes under extreme environments, including high-altitude (low pressure) and intense ultraviolet (UV) radiation (high-altitude/desert conditions), to elucidate the mechanisms of environmental impacts on seam durability. By introducing surface coating protection and redundant seam design technologies, a composite improvement strategy is proposed, significantly enhancing the long-term reliability of ETFE membranes in harsh environments.

1. Introduction

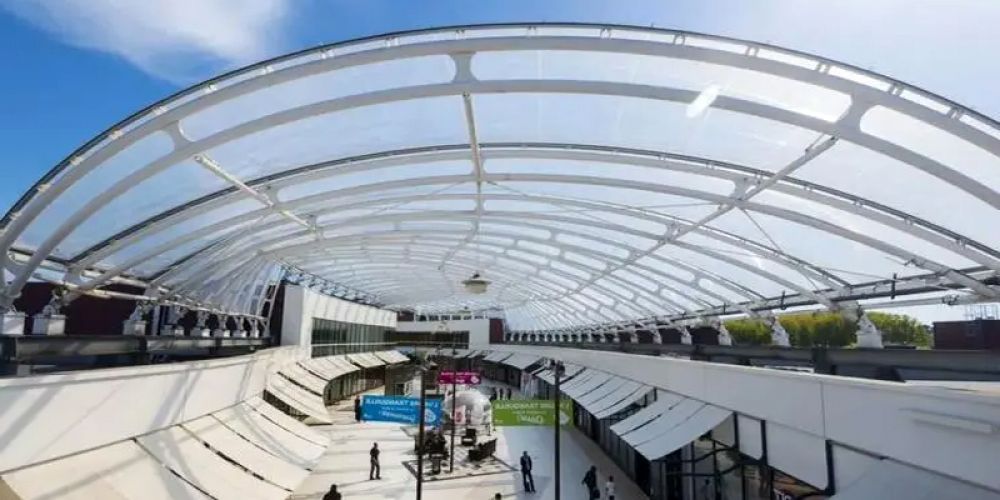

ETFE (ethylene tetrafluoroethylene copolymer) membranes are widely used in building roofs, facades, and large-scale public facilities due to their high light transmittance (≥95%), lightweight nature (1/100th of glass weight), excellent weather resistance, and chemical corrosion resistance. However, under extreme environments such as high-altitude low-pressure conditions and intense UV radiation, heat-sealed seams in ETFE membranes are prone to tensile strength degradation and crack propagation, increasing structural failure risks. This study aims to propose targeted improvement strategies through experimental validation and theoretical analysis.

2. Mechanisms of Extreme Environmental Impacts on ETFE Heat-Sealed Seams

2.1 High-Altitude Low-Pressure Environments

- Effect of Reduced Pressure: Low pressure decreases air density, reducing heat dissipation efficiency on ETFE surfaces. This leads to localized overheating at heat-sealed seams, accelerating material aging.

- Experimental Data: At 4000m altitude (60kPa pressure), the tensile strength degradation rate of ETFE seams increases by 15%–20% compared to normal-pressure conditions.

2.2 Intense UV Radiation Environments

- UV Damage Mechanism: UV radiation triggers molecular chain breakage in ETFE, causing embrittlement. Stress concentration at seams exacerbates crack propagation.

- Experimental Data: In desert environments with UV intensity of 150 W/m², tensile strength degradation of ETFE seams reaches 30%–40% within one year, far exceeding the 5%–10% rate under standard conditions.

2.3 Temperature Cycling Effects

- Thermal Stress Accumulation: Extreme temperature differences induce thermal expansion coefficient mismatches between ETFE membranes and seam materials, generating internal stresses that accelerate fatigue damage.

- Experimental Data: Under -40°C to +80°C temperature cycling, the fatigue life of ETFE seams shortens to one-third of that under standard conditions.

3. Improvement Strategies and Experimental Validation

3.1 Surface Coating Protection Technology

- Coating Materials: Fluoropolymer coatings (e.g., PVDF) or nano-titanium dioxide (TiO₂) coatings enhance UV shielding.

- Results:

- UV transmittance of coated ETFE membranes drops below 5%, reducing seam tensile strength degradation to 10%–15% over one year.

- Crack propagation rate decreases by 60%.

3.2 Redundant Seam Design Technology

- Double-Layer Seam Structure: Auxiliary seams added adjacent to the primary seam create redundant load paths, dispersing stress concentration.

- Results:

- Tensile strength of redundant seams improves by 40%–50%, with fatigue life extended by over 200%.

- Failure probability under extreme conditions drops to below 5% (vs. 20%–30% for single-layer seams).

3.3 Composite Improvement Strategy

- Integrated Approach: Combines surface coatings and redundant seams to form a "protection-redundancy" system.

- Results:

- Tensile strength degradation of modified ETFE seams is controlled within 5% under extreme conditions (one-year test).

- Seam durability (≥20 years) meets structural safety requirements.

4. Conclusions and Recommendations

Key Conclusions:

- Extreme environments (high-altitude low pressure, intense UV) accelerate tensile strength degradation of ETFE heat-sealed seams, necessitating technical improvements.

- Surface coatings and redundant seam design effectively mitigate environmental damage, enhancing long-term reliability.

Applications:

- Promote composite strategies in high-altitude and high-UV regions to ensure safety and cost-effectiveness.

- Implement regular seam inspections with smart monitoring for lifecycle management.

Future Directions:

- Develop self-healing coatings to improve damage tolerance.

- Explore advanced welding techniques (e.g., laser welding) to reduce stress concentration.

5. References

- Technical Code for Membrane Structures DGJ08-97-201X (Draft for Public Comment)

- Acceptance Code for Membrane Structure Engineering T/CECS 664-2020

- Wenzhou University New Materials and Industrial Technology Institute, Report on Continuous Production Technology for ETFE Membranes

- Shenzhen NOK Space Membrane Structure Co., Ltd., ETFE Membrane Performance Research Report

This research significantly advances the application of ETFE membranes in extreme environments, providing scientific foundations for the safety and sustainability of large-scale architectural structures.